Home > Products > Dryalpha special feature

Plating processing technique

The part of the apparatus is precise, and reliability of the contact resistance has been required with gentrification. The surface noble metal (Au) does it to a film of 0.1um - 0.2um in a meaning to consult with about reduction in cost, and it is the present conditions that is aimed for the development of a part having it and same class characteristics more than it. However, because the surface plating layer comes to add to many pinholes, a diffusion to the noble metal surface of the groundwork and insulation thing such as oxidation films produces it for a cause of the contact potential difference by the facing of the different kind metal and can raise the present conditions that come to call instability of the contact resistance.

[ Point of the correspondence ]

- Diffusibility of the groundwork metal-Drop of ionic migration

- Surface slippage-Drop of the coefficient of friction

- Stability of the contact resistance-Reliability

- Workability-Productivity and wetting, Levelling property

- Nonmagnetism-Suppression of high-frequency distortion

- Others

In other words, performance improvement that the pinhole lowers surface energy by metal system of the groundwork and an organic system because it cannot be eliminated by the electroplating less than 2um essentially and gives slippage and rust prevention is effective. In brief, the polar molecule structure that is easy to adhere to a pinhole is superior.

Adhesion mechanism of the polar group of the organic seal aperture treatment agent

Use and effect of the dry alpha

Features

- I can expect a simple certain, good effect. (a lot of solvents are selectable, too)

- The dry alpha reduces the inserting and extracting such as connectors and controls the abrasion at the same time.

- For prevention of pinhole corrosion such as the gilding, the prevention of the initial generation compound, prevention of change of color of the silver product There are a stable effect and strong repressibility.

- The film after the processing is stable with age, and an effect lasts for a long term.

In addition, as for the product after the processing, a difference appears in the performance so as to stand if days pass in comparison with a thing of non-processing. - The film after the law of nature does not invade plastic.(D12HT is excluded)

- Density management is simple and does not influence processing cost either.

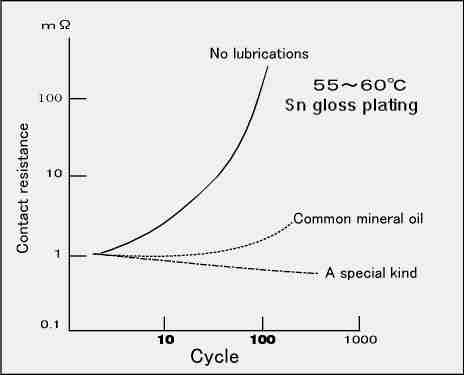

- I recommend use to tin plating materials to prevent fretting corrosion.

- I prevent the oxidation and sulfuration, and the resistance against humidity improves without influence in soldering characteristics after processing, too.

Usage

- Please use the filter device which can remove impurities in the case of use in product line together.

- I splash a solvent with warm air knives after dip lotion or spray at normal temperature more than several seconds.

(In addition, reddish tinges increase by dry time and temperature slightly, but have nothing to do with performance entirely) - I dilute it in ×3-×4 rank depending on a purpose of use, and, please use it.

- When take a step of D1S origin to a silver product, process it with low concentration because ultraviolet rays may act to non-reaction ingredient when handle it at high density; or after processing in IPA light; wash it.

- Even if it is either solvent, please do not use it near open fire.

- Because you are different, in the case of the commodification, please evaluate the effect after the processing by a series of environmental examinations by a plating condition, a kind.

(I am happy if you can talk with us.)

Others

- When I do density of solvent type management, it is thought whether it is easy, and gravimetry management by the heating is appropriate.

(I measure around 10 g to a aluminum laboratory dish and measure a residual substance after having vaporized only a solvent with ovens again.) - There may be a reddish tinge in liquid in itself under the influence of long-term safekeeping and ultraviolet rays, but does not influence performance at all.

- Because there is a thing invading the plumbing part made by vinyl chloride by a solvent, please warn him.

- Because there are the following products by a solvent, please examine it.

- As for the E,B,M type, basic processing solution levels become 0.5% wt with approximately ×4 for this agent 1 (the weight ratio)(product 1: solvent 3), and, as for the P,H type, basic processing solution density becomes 1% in approximately ×2.6-×2.8 for this agent 1 (the weight ratio).

| Product name | Solvent | Dilution solvent |

| D1S20E D1S20P D1S20B D1S20M E1S series S1 series SA series D1SWG |

Avian chlor ethylene Isoparaffin Propyl bromide Methylene chloride I apply to the solvent mentioned above Isoparaffin Isoparaffin Emulsion type |

Trichloroethylene Isoparaffin,IPA Propyl bromide Methylene chloride IPA,Isoparaffin IPA、Isoparaffin others Pure water |

Reference : A dilution solvent of D1S20P includes IPA by the possibility, but, please move it to the processing tank in the state that it was dried before processing enough because water is easy to be mixed.

Also, thank you you can consult and ordering together so you can also offer other solvent type.

Sisters product : S1 series(Because it has slippage which is better than D1S system, be accompanied, and, please use it for the gilding, and it lightly features silver, tin, nickel that there are few color changes after the processing again.)

SA series(I can use it for silver, tin and others with the change of color inhibitor of the strong dry type and have superior slippage.)

D0S(It is superior to D1S in silver.)

Alphamist(I have D1S and a characteristic of the abbreviation equivalence by a spray type.)

The slightly slide abrasion of the connector and the organic system.

Differences between inorganic system and organic system

Increase of the contact resistance produces the connector by a periodic repetition campaign of the small amplitude to call fretting.

Generally this main cause calls this process with fretting corrosion "slightly slide abrasion corrosion" for reason to be taking place by the abrasion powder which collected with oxide.

An effect that the seal aperture treatment agent does not only seal up merely pinhole and prevents outbreak of the abrasion is necessary and primarily is decrease of the abrasion, second to wash off abrasion powder including oxide from self-cleaning and the contact surface if I raise important mechanism to be provided from there.

And the most important thing is that there is work to send oxygen from the surface and is to in this way prevent abrasion powder and surface oxygenation.

It may be said that the dry model that this point is the difference between dry model and seal aperture treatment agent of the wet model, and is complete has a short life.

Use choice list

※The results are different by plating specifications, a kind. Please use it for reference.

Specifically, please refer to the person in charge.