Home > Products > Dryalpha special feature

Static contact resistance evaluation after the environmental examination

(Gold-plated board direct evaluation)

Mixture gas, hydrogen sulfide 3ppm oxidation sulfur 10ppm, 40 degrees Celsius, 75% RH, 48 hours later

Measurement probe = Pt, 1 φ, It is groundwork Ni plating 1.0um+ gilding 0.1um to 0.5R sample = C2680 board.

Silver contact operation measurement of the force evaluation(by according to processing)

- Measurement condition(Silver:Silver,Surface coarseness approximately 0.6-0.8μm)

- Probe(Silver,1φ,2R,20g)

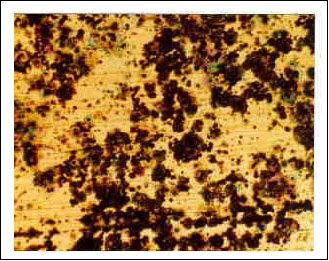

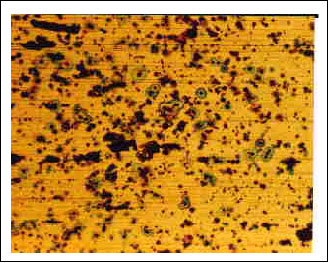

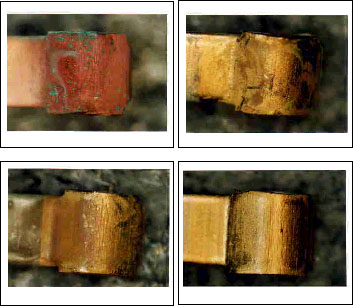

Corrosion resistance test result micrograph

Mixture gas SO2 10ppm+H2S 3ppm、40℃,75%,96 hours

It is nickel plating 1.0um on the C2680 groundwork,Gold-plated 0.1um

|

No processing Because, as a matter of course, the gold-plated thinness is high in the corrosion coefficient of the mixture gas, corrosion considerably awfully advances than a pinhole. |

|

Aqueous group of other companies I prevent some pinhole corrosion, but there are not other characteristics at all. |

|

D1S group of our company I completely suppress the pinhole corrosion, and the general performance of contact resistance, etc. is extremely high, besides, too. |

The function required by the point of contact materials such as connectors is corrosion-resistant, and good slippage, wear resistance, contact resistance, spring characteristics are important.

Salt water mist test result

It is thought that there is a gas corrosion examination in the first field seeing from the real use environment where evaluation examination connection of the electric contact mechanism part includes a salt water mist examination. But a salt water mist examination exists as trouble analysis of electronic equipment put as an exception near the shore.

Because an insulating problem becomes the big factor when it is electrolysis corrosion theoretically, primarily I do not think for the issue of contact.

The lower photograph shows the result that 30 degrees Celsius, 96-hour salt water aerification examined the plating sample which is bad (processing is bad) of the condition.

(The conditions such as the processing density are reference by the recommended density of each maker.)

| No processing | Solvent group of other companies(2) |

| |

| Solvent group of other companies(5) | Solvent group of our company |

Initial contact resistance properties of the processing film

Goldplate:Gold alloy probe,1Φ,0.5R(STATIKS)