Home > Products > Dryalpha special feature

Electrical wet resistant evaluation of the contact oil(Cu,Ag,Au)

I measure resistance against humidity ability in each metal using 2 very sensitive electrode V-I properties assay as a resistance against humidity evaluation of lubricator (point of contact oil and others) used for contact materials.

In general, as for the electric current which drifts when I apply the voltage between electrodes more, it is on a non-straight line for the voltage across the thin organic matter between various metal bipolarity, and, as for the conduction mechanism of the electric current at this time, the electric current through the conductor of the film, a tunneling current, an ion current are thought about.

In addition, a tunneling current becomes more dominant, and it is good, and it is studied the electronic tunneling effect through the metal oxidation film in film conduction such as the organic matter like the case of the vacuum even at the age of organic matter by an effect of the quantum study, but an insulator reports it because I think about a film characteristic of contact oil used for the purpose of stabilization of the electricity contact resistance because there are few study documents about the characteristics of the contact oil and evaluated it partly.

The contact oil intervening between two electrodes of the contact part is used for a purpose to stabilize the contact resistance of the point of contact as a kind of electrolyte and helps reduction of the contact resistance now if conditions of the point of contact mechanism region namely a metal kind and constitution, a surface electric charge, contact, a shape, a plating condition examine V-I condition and the ionicity of the partial change - electrolyte by the outside energy, oxidation-reduction, absorbency, V-I condition, pollution existence machine gas enough more particularly.

It is in particular to restrain type B conduction above all to lower contact resistance if two kinds of a thing letting the electrode particles such as ions undertake current transportation exist and do type A, the latter with type B in the former that a conductive electron just passes between both electrodes in the electrode interface.

There must not be water in the interface to seize type B and therefore should use the matrix keeping out water for the interface. Furthermore, it is to have the property that removes this if no plane and an organic semiconductor material do not occur in an interface or it occurs.

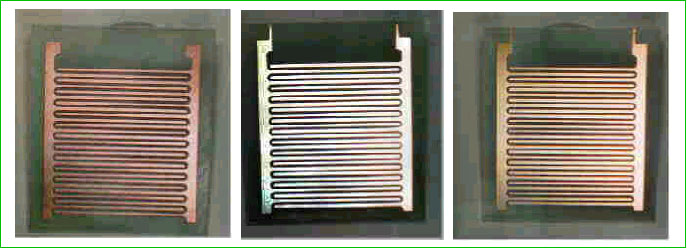

The sample photograph which evaluated resistance against humidity in the final examination

- Example of the Cu board

- Example of the Ag board

- Example of the Au board

Evaluation examination of the contact oil under the high temperature high humidity

I-V converter connection diagram

There is the shift of the electrode at the time of the use, and an electrostatic charge adsorption is more important to the point of contact metal electrode of the contact part a problem of the physical adsorption of the additive which is appropriate for the initial and occupied environment outside energy an early electric charge by brighteners a metal kind, a composition (alloy etc. of the 3-4 ingredient) plating condition for the characteristic of the test method, and the connection that is in this way close to resistance against humidity and structure is seen. Do it, and feel; and by this test method with the adsorption power of the additive and the metal is appropriate, and various effects including the electromotive force appropriate addition quantity become clear definitely.

A test method and evaluation standard

I used the contact oil which was an electrolyte for a comb type print electrode board using such an electrolytic wet resistant bath. The change of the V-I characteristic produces a kind, a metal kind, groundwork metal constitution organicity kind of inhibitor and the density by the pinhole of electrolyte by combinations more when I apply the voltage with various metal as 1mm in the electrode interval. The voltage - electric current curve of this time has a relationship such as the chart below.

|

Generally, there are few electric currents first, but there is a point of the voltage that an electric current begins to be passed to suddenly, and it is said with a rest electric current by the resolution voltage and the electric current which drift before it is said and reaches the resolution voltage in this, and the strength and weakness of the electric charge characteristic become clear when I compare the potential difference that applied the early stage of voltage by organic inhibitor adsorption and addition density and electromotivity pressure under conditions of V=0. The problem of this point may think about being careful here as a kind of the evaluations concerning the smallest overvoltage and electric current for hydrogen outbreak and the oxygen outbreak, but appropriateness of the voltage is important to make organic inhibitor effect clear, and around 1-100mV is desirable. |

But, as for the theory resolution voltage of the water, as for the real resolution voltage, it is to approximately 1.6-1.7V at 1.23V when I really assume environment of the high temperature high humidity, and 1V(max) is relatively appropriate, and the characteristic of the electrolyte is good, and the evaluation voltage of the contact oil can understand the organic inhibitor case in lower than 100mV because hydrogen and oxygen no longer occur.

However, I can evaluate the contact oil at the D point which an electric current flows through with an electrode potential - electric current curve suddenly, but even the electric potential that I begin it on an electrode, and gas occurs can be decided.

In addition, the smallest overvoltage for the hydrogen gasification varies according to the metal kind of the point of contact, and the order is similar to the data such as documents, too.

For example, I refer to the following metal order.

(Ex)Pt,Pd,Ru,Au,Fe,Co,Ag,Ni,Cu,Cd,Sn,Pd,Zn,Hg(High)

| V-Ⅰcharacteristic of Dryalpha | V-Ⅰcharacteristic of bad product of the resistance against humidity |

| |

| There were not the change of color of each sample, the corrosion at all after 60 degrees Celsius, 98% RH, 120H | A change of color of Cu was seen on the condition, and VI properties worsened |

Documents:A polarization and VI properties of the contact oil under the high temperature high humidity and others (for one of an organic film intervening between two electrodes an evaluation by the potential difference of a battery)

株式会社スリーボンド 本多 務

Influence on metal,Resin of dryalpha D1S type(The solvent does not include it)

- I perform the following corrosion examinations based on JIS K2220( 5.5) copper sheet corrosion test method and show a surface state after the rule time.

- I soak each ground metal sample into base oil (before solvent dilution) and confirm a change of color state of the metal plate after having maintained it at 100 degrees Celsius for 24 hours.

| Copper | Brass | Sub-copper | Nickel | 鈴 | Aluminum | Silver | goldplate |

| 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 |

3.The goldplate (Ni-2um groundwork, Au-0.2um) that the corrosion was not accepted for all examination metal as things mentioned above.

Influence on plastic

- Because I pass a firing styrene application examination (60 degrees Celsius, 24 hours) considered to be the severest, I can use it for the following resin in peace.(D12HT is excluded)

| Resin name | The good or bad |

|---|---|

| ABS PBT (Polybutyl terephthalate) PC (Polycarbonate) PE (Polyethylene) PP (Polypropylene) Nylon Polyacetal (Duracon) PVC (Vinyl chloride) PS (Polystyrene) |

〇 〇 〇 〇 〇 〇 〇 〇 |

Influence to give to insulation resistance

- The results that I use conduction degree measurement cell, and measured electrical resistance of 1cm with the measurement voltage of 100V in 60 degrees Celsius, 95% RH are as follows.

| Just after an examination start more than 500MΩ | More than 500 hours later 500MΩ |

Kind of lubricator

The used rust prevention oil of the contact of the mechanism part, the number of grease are a great variety of and think that there are many contents to examine on using it.

The complicated characteristic of the contact mechanism part seems to appear from these purpose of use metal and plating distinction so that natural test results are different with the same manufacturing method product.

About such a rust preventing agent, I want you to refer to it because you analyzed past documents and the product.

- The composition forms are classified in oil, grease, dry state;

as constitution basis oil, an oxidation stabilizer, a gelling agent, a metal inert agent, a clay index improver, a dispersion cleaner, an oiliness improver, metal powder, a rust prevention additive, a color, dye, plastic - Kind of the basis oil(Alone and mixture)

(A)Mineral oil: paraffin series,naphthenic,unique-made essential

(B)Synthetic oil: Diester 2-ethyl hexyl(Sebacate,adipate) and

C oxoalcohol,Neo-pentyl polyol ester,Caproic acid

(Pentaerythritol ester),2エイルヘキシル酸

(トリメチロールプロパネステル),ペンタエリストールカプリン酸

Ester,Phosphoric acid ester,Silicate ester(テトラアルコキシミラン)

Polyphenyl ether,Polyalkylene glycols,Olefin polymerization oil

Fluorine,Synthetic C.H oil,Vegetable oil denaturation fatty acid

(C)Silicone composition oil: フロロ、Methyl phenyl,Dimethyl,Fatty acid denaturation

Aminodenaturation,Alkyl denaturation,Methyl hydrogen,Mercaptodenaturation

Polyether,Polyoxyalkylene denaturation,Polyamine denaturation

Carbamic denaturation,Stearylamine(Hydrochloric acid group) - Gelling agent: Lithium soap,Aluminum composition soap,Mixed soap,Silica(Silane coupling processing)

Lead soap,Calcium soap,アリルウエア,Polyurea

Phthalocyanine,Silica soap mixture,Terephthalamate,Fluorine compound - Others: Polymethacrylate,Polyacrylate,Ethylene(Propylene copolymer)

Organic calcium,Organic magnesium,Organic barium,Organozinc

Organic lead,Organotin,Metal oxide,Gold,Silver,Copper,Amine compound,Phenol compound

Sulfur compound,Phosphorus compound,Polyisobutylene,Chelate compound

Fatty acid(Oleine,Adipic acid)

It is mixed a lot of, and these chemical things are a field of the machine oil and similar specifications, but the different point is about a kind of the partner metal, purity, terms of use, a rating system, the refinement degree of the lubricant, stability, and what I note it and use is important enough.